Top 10 Flexible Packaging Bag Making Machines

-

I. Multifunctional Food Packaging Bag Making Machine: The Art of Balancing Food Safety and Efficiency :

Technical Characteristics

Multifunctional food packaging bag making machines adopt modular design, typically equipped with high-precision photoelectric tracking systems, multi-axis servo control, and food-grade contact materials. Advanced models integrate automatic correction, tension control, and online inspection functions to ensure flat bag bodies and tight seals. Specially designed cross-sealing and longitudinal sealing mechanisms can adapt to various composite materials, including common food packaging materials like PET/PE, NY/PE.

Key Selection Factors

Hygiene Standards: Must comply with food contact material regulations such as FDA, EU 10/2011.

Flexibility: Quick mold change systems to adapt to the production of food bags with different sizes and shapes.

Seal Quality: Constant temperature control systems ensure seal strength, preventing food leakage or spoilage.

Production Speed: High-speed models can reach 200-300 bags/minute, meeting large-scale production demands.

-

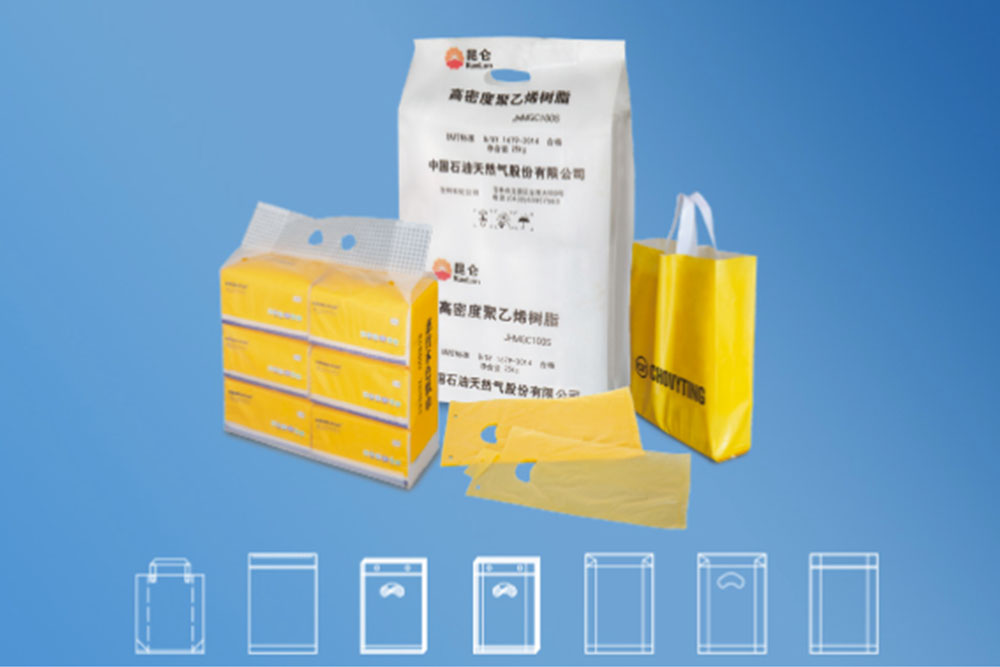

II. Woven Bag Making Machine: Professional Solution for Industrial-Grade Strength :

Technical Features

Woven bag making machines are specifically designed for handling polypropylene (PP) and polyethylene (PE) woven fabrics, equipped with heavy-duty feeding mechanisms and high-strength sewing or heat-sealing devices. High-end models integrate automatic cutting, hemming, and synchronous printing functions, utilizing industrial-grade PLC control systems to ensure stability under continuous high-load production.

Application Scenarios and Selection Points

Bag Type Classification: Open-mouth bags, valve bags, square-bottom bags, etc., for different industrial uses.

Strength Requirements: Select corresponding structural strength based on the weight of the contents (ranging from 25kg to 2 tons).

Printing Capability: Consider whether integration of flexographic printing or post-printing interfaces is needed.

Environmental Adaptability: Dust-proof design and wear-resistant components are crucial for woven bag production environments.

-

III. Non-woven Bag Making Machine: Technological Evolution Under the Environmental Trend :

Technological Development

Non-woven bag making machines have developed rapidly with the popularity of eco-friendly shopping bags, employing ultrasonic welding or heat-press sealing technology to avoid the use of adhesives. Modern models are equipped with precise tension control systems to address the challenge of uneven elasticity in non-woven materials, while integrating automatic handle installation and pattern alignment functions.

Selection Considerations

Welding Technology: Choice between ultrasonic welding (suitable for PP non-woven fabric) and heat-press sealing (suitable for PET non-woven fabric).

Handle Type: Different configurations for punch-type, paste-type, or integrally molded handles.

Production Efficiency: High-speed models can reach 120-150 bags/minute, meeting the demands of supermarkets and retail.

Customization Capability: Adaptability to various sizes, thicknesses, and colors of non-woven materials.

-

IV. Side Seal Bag Making Machine: Efficiency Expert for Basic Bag Types :

Working Principle and Technical Characteristics

Side seal bag making machines form three-side seal bags through longitudinal sealing and transverse cutting, making them one of the most widely used bag-making types. They use continuous web feeding, equipped with high-precision length setting systems and constant temperature sealing blades. Advanced models feature automatic waste recycling and real-time quality monitoring systems.

Applicable Materials and Selection Points

Material Range: Suitable for various flexible packaging materials such as films, composite materials, and aluminum foil.

Seal Quality: Double-sided heating and cooling press systems ensure flat and strong seals.

Size Range: Width from 50mm to 1000mm, length from 80mm to infinite continuous bags.

Special Requirements: Consider whether functions like anti-static treatment, inflation, or oxygen absorber placement are needed.

-

V. Bottom Seal Bag Making Machine: Professional Producer of Three-Dimensional Bag Types :

Structural Characteristics

Bottom seal bag making machines transform flat film into a three-dimensional structure through unique forming units, creating bags with bottom seals and side gussets. This bag type has excellent stand-up ability and superior shelf display effect. The equipment integrates multi-channel creasing systems and reinforced bottom sealing mechanisms.

Application Fields and Selection Criteria

Main Applications:Retail packaging for food, cosmetics, electronic products, etc.

Forming Precision: The machining precision of the 3D forming unit directly affects the regularity of the bag shape.

Bottom Seal Strength: Multi-layer materials or heavy products require reinforced bottom seal structures.

Extended Functions: Consider whether additional functions like zippers, easy-tear notches, or hanging holes need to be integrated.

-

VI. Vest Bag Making Machine (Handled Bag Making Machine,T-Shirt): The Packaging Workhorse of the Retail Industry :

Technical Features

Vest bag making machines are highly integrated equipment, completing bag forming, handle punching, and overall sealing in one go. They employ continuous rotary punching dies and synchronous tracking systems to ensure precise handle positioning. High-end models are equipped with dual-channel production systems, doubling efficiency.

Production Considerations

Handle Type: Different process requirements for punch-type, semi-circular, or full-perimeter punched handles.

Material Saving: Optimized layout and punching path design to reduce scrap.

Production Speed: High-speed models can reach 200-250 bags/minute, meeting peak supermarket demands.

Durability: The material and heat treatment process of the punching dies directly affect equipment lifespan.

-

VII. Continuous Roll Bag Making Machine: Paradigm of Efficient Continuous Production :

Working Mode

Continuous roll bag making machines produce unbroken rolls of bags for users to tear off as needed. They employ perforated (point-break) or micro-perforated easy-tear designs, equipped with precise cutting control and winding tension systems. Particularly suitable for large-scale production of daily consumables like (fresh-keeping bags) and garbage bags.

Technical Selection Points

Easy-Tear Design: Perforation depth control technology ensures easy tearing without spontaneous breakage.

Winding Quality: Tension control and correction systems ensure neat and tight winding.

Production Speed: Can reach up to 400-500 bags/minute, making it one of the most efficient bag-making types.

Slitting Options: Consider whether online slitting into smaller rolls or custom roll diameters is needed.

-

VIII. Diaper Bag Making Machine (Sanitary Product Packaging Machine): Combining Hygiene Standards and Flexibility :

Special Requirements

Diaper bag making machines are specifically designed for sanitary products and must meet medical-grade hygiene standards. The equipment adopts fully enclosed design and easy-to-clean surface treatment, equipped with oil-free lubrication systems and HEPA-filtered positive pressure protection. The material handling section is specially designed to avoid stretching or deforming the soft non-woven fabric.

Key Selection Factors

Hygiene Certification: Compliance with medical device production standards like GMP, ISO 13485.

Gentle Handling: Low-tension conveying and sealing systems to protect sensitive materials.

Odor Control: Low-temperature sealing technology to reduce material odor generation.

Integration Capability: Synchronous control systems for direct connection with diaper production lines.

-

IX. Ziplock Bag Making Machine: Technological Realization of Convenience Packaging :

Technical Complexity

Ziplock bag making machines are among the most technologically advanced bag-making equipment, requiring the synchronous embedding or forming of zipper structures during the bag-making process. They utilize precise thermoplastic forming or zipper tape implantation technology, equipped with multi-stage temperature control and pressure adjustment systems.

Production Considerations

Zipper Type: Different process requirements for single-track, double-track, colored, or transparent zippers.

Sealing Performance: Double sealing at the junction of the zipper and bag body ensures leak-proof performance.

Alignment Accuracy: High-precision alignment between the zipper and bag opening is key to quality.

Multi-function Integration: Consider whether simultaneous integration of easy-tear notches, hanging holes, or anti-counterfeiting marks is needed.

-

X. Tissue Bag Making Machine: High-Speed Processing Expert for Soft Materials :

Professional Characteristics

Tissue bag making machines specialize in handling soft, fluffy tissue materials, employing low-pressure conveying and folding systems to avoid product compression and deformation. They are equipped with automatic filling and sealing synchronization devices, achieving complete production line integration from tissue folding to packaging.

Selection Points

Gentle Handling: Pneumatic conveying and buffering systems to protect tissue integrity.

Sealing Adaptation: Optimization of heat-sealing parameters for composite materials containing paper fibers.

Production Linkage: Synchronous control and data exchange capability with upstream tissue folding machines.

Hygienic Design: Dead-angle-free design and food-grade material contact components.

Ultimate Selection of Bag Making Machines: Comprehensive Evaluation Framework

Material Compatibility Analysis

Material type (film, non-woven fabric, woven fabric, composite materials)

Material thickness range (from 0.01mm to 2.0mm)

Material properties (stretchability, heat sensitivity, friction coefficient)

Production Parameter Matching

Production speed requirements (bags/minute)

Bag size range (length, width, thickness)

Changeover time and flexibility

Quality Control System

Online inspection capability (visual inspection, weight inspection, leak detection)

Process control precision (temperature, pressure, length control)

Data traceability and statistical analysis functions

Energy Efficiency and Sustainability

Energy consumption indicators (kWh/10,000 bags)

Material utilization rate (scrap ratio)

Maintainability and component lifespan

Supplier Evaluation Dimensions

Technical support and training systems

Spare parts supply and response time

Equipment upgrade and modification capabilities

Supplier Evaluation Dimensions

Technical support and training systems

Spare parts supply and response time

Equipment upgrade and modification capabilities