Very Strong Wallboard and Assemble of Flexo Printing Machine

Advanced calibration ensures perfect color alignment(no blurry edges or mismatched hues),while heavy-duty parts and strict quality can guarantee smooth operation even at high speed.

Durable construction means fewer breakdowns,less downtime,and consistent results batch after batch,wheter printing lables,packaging or films.

The Four Major Application Areas of Flexographic Presses: The Ultimate Choice Among

-

I. Gearless CI Flexographic Press: The Paradigm of High Precision and Flexibility :

Technical Principle and Structural Features

Gearless CI flexographic presses utilize servo drive technology to replace traditional mechanical gear transmission systems. Each printing unit is driven by an independent servo motor, achieving multi-color registration via a central impression cylinder (CI). Its core advantages lie in eliminating registration errors caused by gear backlash while allowing independent adjustment of the circumferential and lateral positions of each printing unit during machine operation.

Application Advantages in the Bag-Making Field

Ultra-High Registration Accuracy: Suitable for high-end food packaging bags, cosmetic stand-up pouches, and other products with extremely high demands for pattern fineness. Minimum registration error can be controlled within ±0.1mm.

Quick Plate Change and Setup: The servo drive system supports preset printing parameters. Job changeover time can be reduced by 30%-50% compared to gear-driven models, significantly enhancing short-run production capability.

Wide Material Adaptability: Capable of stably printing various bag-making materials with thicknesses ranging from 12μm to 250μm, including PE, PP, OPP, aluminum foil composite films, etc. Particularly suitable for precision printing on multi-layer co-extruded films.

Integration with Automated Bag-Making Lines: The gearless design facilitates digital linkage with automatic tension control, online defect detection systems, and subsequent bag-making processes (such as slitting, heat sealing, punching), enabling the construction of intelligent bag-making production lines.

Applicable Scenarios and Selection Recommendations

Ultimate Choice Scenario: When a company primarily undertakes orders for high-end brand packaging bags, pharmaceutical packaging bags, etc., with stringent printing quality requirements and characterized by multiple varieties and small batch sizes, the gearless CI flexographic press is the optimal investment choice. Its relatively high initial investment can be quickly recouped through reduced waste rates, lower job changeover losses, and enhanced premium pricing capability.

-

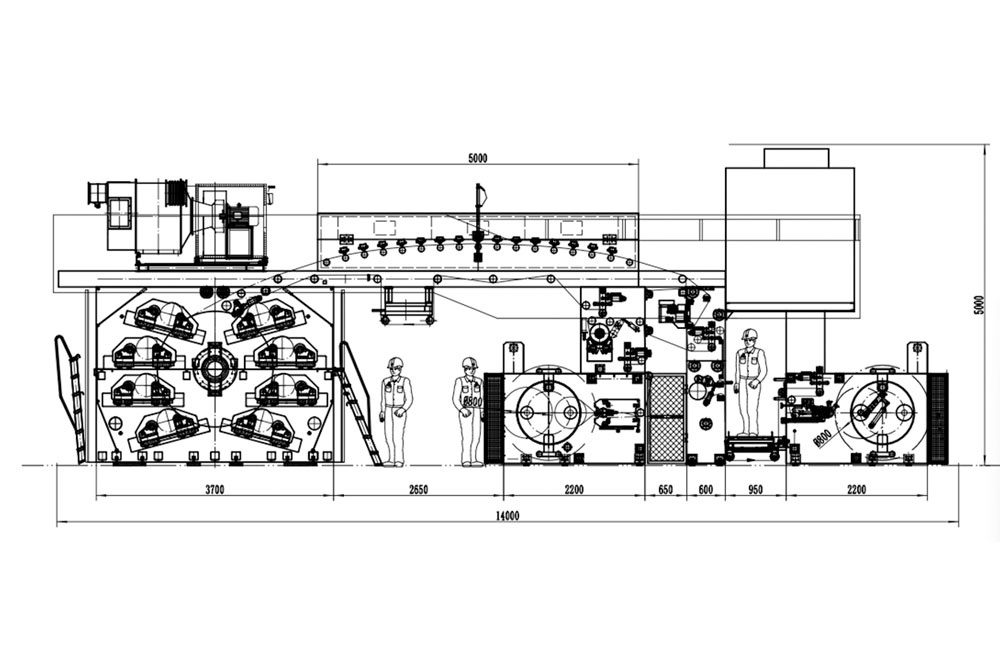

II. CI Gear Flexographic Press: A Stable and Efficient Mass Production Solution :

Technical Principle and Structural Features

CI gear flexographic presses use a mechanical gear system to synchronously drive each printing unit, performing printing around a large central impression cylinder. With a robust structure and stable transmission, it represents the classic design of traditional flexographic printing technology.

Application Advantages in the Bag-Making Field

Exceptional Operational Stability: Mechanical gear transmission offers high reliability during long-term high-speed operation and relatively simple maintenance, making it especially suitable for 24-hour continuous production modes.

Excellent Solid and Full-Bleed Printing Results: The central impression cylinder structure provides uniform, consistent pressure, resulting in fuller and more even ink transfer. Ideal for products like shopping bags and eco-friendly carry bags with large solid color areas and full-bleed printing.

High-Speed Production Capacity: Designed speeds typically reach 300-600 meters per minute, making it ideal equipment for large bag-making factories producing high volumes of standard products (e.g., common T-shirt bags, flat bags).

Outstanding Cost-Effectiveness: Compared to gearless models, it has lower initial investment and maintenance costs, offering clear unit cost advantages in long-run printing.

Applicable Scenarios and Selection Recommendations

Ultimate Choice Scenario: Suitable for enterprises primarily supplying large supermarkets or producing standardized industrial packaging bags, where order characteristics include large batches, relatively fixed patterns, and cost sensitivity.

The CI gear flexographic press is a reliable cornerstone for achieving economies of scale and ensuring stable delivery.

-

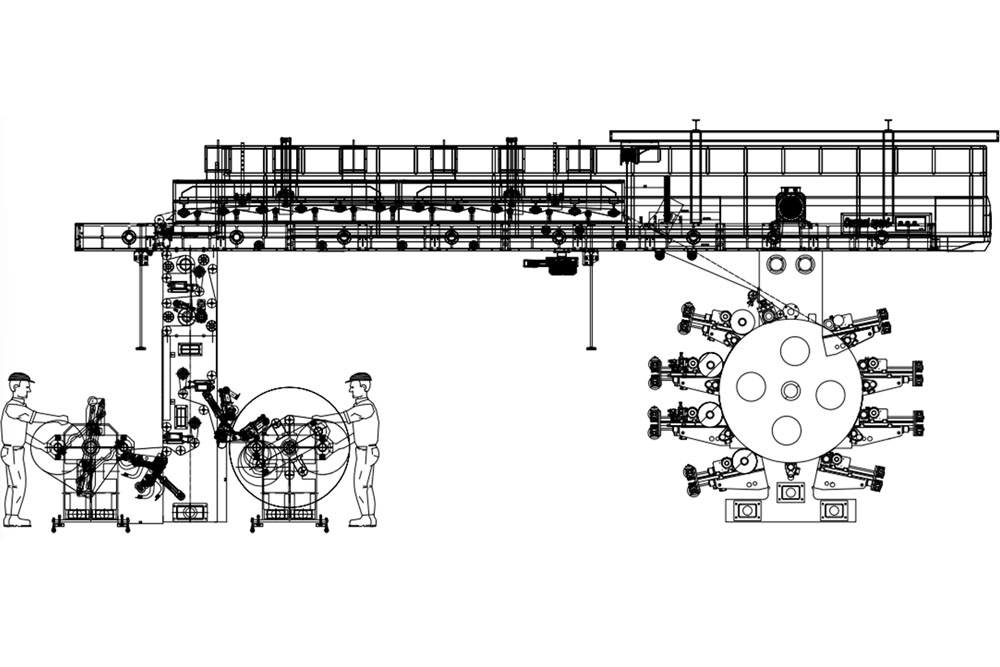

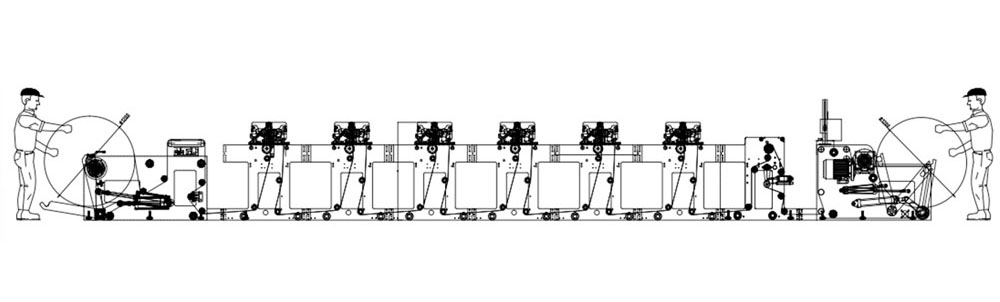

III. Unitized flexographic printing press: The Representative of Versatility and Modularity :

Technical Principle and Structural Features

The printing units of an inline flexographic press are arranged horizontally, each with its own impression cylinder. The substrate travels in a straight line between units. This layout offers great configuration flexibility.

Application Advantages in the Bag-Making Field

Unparalleled Process Extensibility: Can easily integrate inline processing units such as cold foiling, die-cutting, laminating, and varnishing, enabling one-stop "printing-finishing" production. Particularly suitable for producing structurally complex bags like stand-up pouches, zipper bags, and shaped bags.

Superior Drying Performance: Each printing unit can be equipped with an independent drying system, suitable for printing with high-opacity white ink or special inks (e.g., water-based inks), preventing blocking.

Facilitates Inspection and Maintenance: The open structure allows operators easy access to each printing unit, facilitating print quality monitoring, quick cleaning of anilox rollers and plate cylinders, and enhancing production flexibility.

Adapts to Various Material Thicknesses: By adjusting tension at each unit, it can handle materials from extremely thin films to thicker paper-based substrates, meeting the needs of bag-making with different materials.

Applicable Scenarios and Selection Recommendations

Ultimate Choice Scenario: Suitable for medium to large bag-making enterprises with diversified product lines that frequently require special printing effects or inline processing. When a company produces not only standard packaging bags but also high-value-added products like premium gift bags and multi-functional convenience bags, the versatility of the inline flexographic press is an irreplaceable advantage.

-

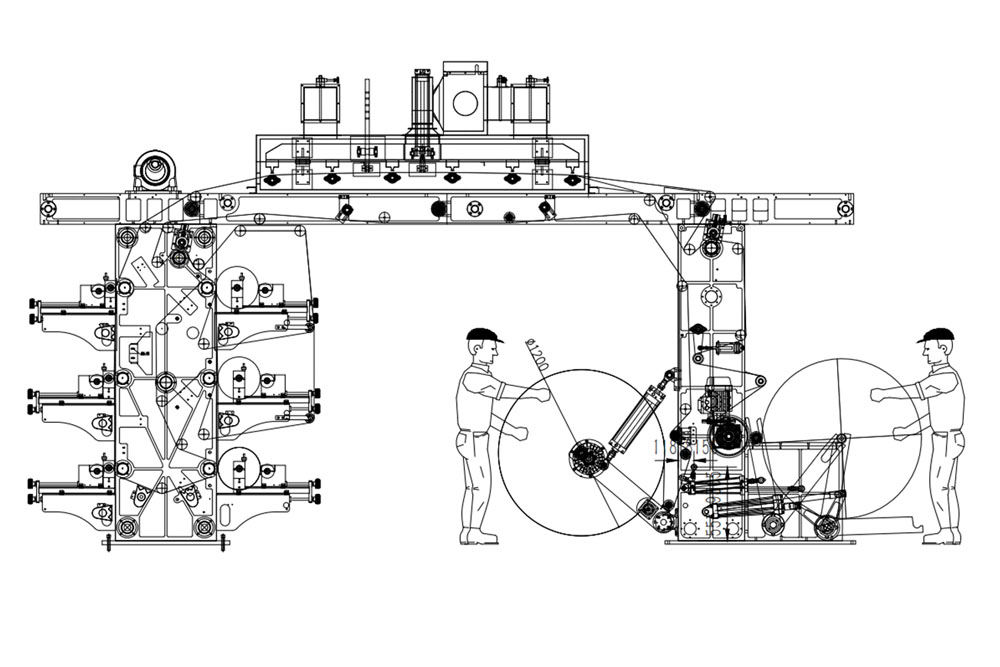

IV. Stack Flexographic Press: The Compact and Economical Choice for Entry-Level and Specialized Applications :

Technical Principle and Structural Features

The printing units of a stack flexographic press are stacked vertically or at an angle, resulting in a compact structure and small footprint. The substrate passes sequentially through the vertically arranged printing units to complete multi-color printing.

Application Advantages in the Bag-Making Field

High Space Utilization: The footprint is typically only half that of a CI press with the same number of colors, making it suitable for small and medium-sized bag-making factories with limited workshop space.

Good Accessibility: Despite the compact structure, modern designs usually ensure adequate operating space for each unit, facilitating plate changes and daily maintenance.

Optimal Economy: Among the four types, it has the lowest initial investment and is an ideal entry-level model for entering the flexographic printing field.

Suitable for Specific Materials: Performs stably and reliably when processing absorbent materials like paper and non-woven fabrics, as well as thicker eco-friendly plastic bag materials.

Applicable Scenarios and Selection Recommendations

Ultimate Choice Scenario: Primarily recommended for start-up bag-making enterprises, small factories mainly producing ordinary shopping bags and simple color-printed packaging bags, or as supplementary equipment in large factories for producing bag products made from specific materials. When budget and space are primary constraints, and there is no high demand for ultra-high registration accuracy or inline functionalities, the stack flexographic press offers the best cost-performance ratio.